Maximize Filter Cartridge Life with Regeneration

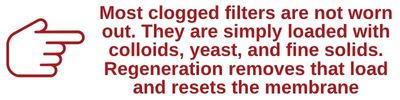

Membrane filter cartridges are an essential tool for wine clarity and microbiological stability, but they do not have to be a disposable expense. With the right regeneration practices, wineries can restore flow, maintain sterility, and significantly extend cartridge life, which reduces both cost and waste.

Instead of replacing filters as soon as they show pressure spikes or reduced throughput, regeneration allows winemakers to return a used cartridge to near-new performance. The result is better filtration economics and more predictable bottling runs.

The Case for Regeneration

✔ Restores flow and keeps pressures low

✔ Preserves pore integrity for sterile filtration

✔ Minimizes premature replacement

✔ Reduces landfill waste and supplier spend

✔ Protects wine quality through consistent performance

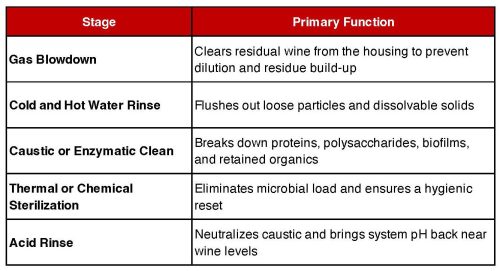

Typical Regeneration Cycle

How Long Can a Cartridge Last?

With proper regeneration, many wineries report 8 to 15 full regeneration cycles per final membrane filter, sometimes more. Service life depends on:

- Upstream clarification, including fining, DE, crossflow, or centrifugation

- Filtration pressure management

- Correct chemical concentration and temperature

- Whether regeneration is performed immediately after use

In short, cartridges rarely fail because of membrane damage. They fail because they are not cleaned correctly or often enough.

Best Practices for Winemakers

1. Treat regeneration as a written SOP, not an optional step.

2. Match cleaning chemistry to wine style and load.

3. Track cycles and operating pressures to catch early performance decline.

4. Train cellar teams to avoid over-pressurizing membranes.

5. Verify sterility regularly. Testing is cheaper than spoilage.

For Eaton Cartridge Users

The principles above should apply to most wine-grade filter cartridges. They are particularly relevant for Eaton Membran PS Wine and PS Plus cartridges, which are designed to be regenerated multiple times while maintaining filtration integrity. ATPGroup supplies these cartridges along with Eaton’s complete line of filtration media and can provide technical guidance on regeneration chemistry and procedures.

For more detailed information on how to maximize the life of your filters, download our step-by-step guide:

ATPGroup’s team of enologists and technical specialists can help design a filter cartridge management program that works with your cellar workflow. For more information, contact your ATPGroup Technical Representative or Enology Products Specialist, or call (707) 836-6840.